Larger excavators are increasing in popularity as the focus turns to cost per ton. The 186,070- to 192,464-lb (84,400- to 87,300-kg) Hitachi ZX890LC-6 fills this need for a larger excavator to optimize production and offers the advanced technology you need to manage operations.

Over the past decade, the typical size of excavators used in quarries has continued to grow as operators seek to reduce cost and improve productivity. The larger machines often allow the aggregate producer to move more tons per gallon of fuel burned. This is critically important in a time of fuel price volatility.

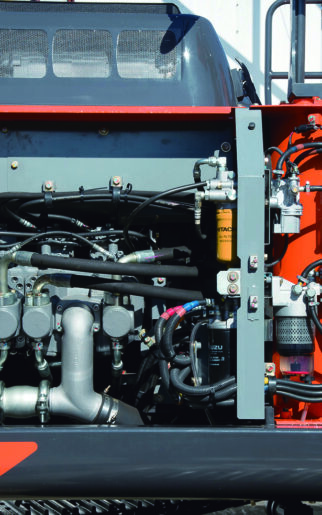

Larger machines also tend to consume more fuel per hour, which makes machine efficiency a major consideration. A machine that maximizes hydraulic system performance while minimizing losses and inefficiency provides a competitive advantage. The Hitachi ZX890LC-6 uses the HIOS IIIB hydraulic system that employs two pumps and two control valves to reduce fuel consumption without compromising performance. The advanced hydraulic capabilities increase the front-end speed, reducing pressure loss and increasing operating capacity. These advanced hydraulics and increased arm and boom speed make the ZX890LC-6 the ideal excavator to load rock trucks day after day for optimum quarry operation.

Sized for the job

While the excavators in the quarry continue to increase in size, it is still important that they match other equipment in the hauling and crushing system. The size of support equipment such as trucks, crushing and screening plants is also increasing. The size of the primary crusher has a large influence on sizing the excavator. In addition, a balance must be reached between an excavator standing idle waiting for haul trucks or having trucks waiting to be loaded.

The Hitachi ZX890LC-6 standard bucket capacities range from 2.49 to 6.54 yd3 (1.9 to 5 m3). With its 512 horsepower (381.8 kW) T4F Isuzu engine and HIOS IIIB hydraulic system, the ZX890LC-6 meets the demands of loading trucks and moving large amounts of material, 24/7 in the quarry. This kind of performance demands quick cycle times. The ZX890LC-6 has a smooth and powerful loading cycle while remaining fuel efficient with features such as auto idle and auto shutdown when waiting for the next round of haul trucks.

Hitachi prioritizes safety

Safety is a priority on any quarry site. The Hitachi ZX890-6 responds with technology and simplified machine access to protect operators and service personnel. A wide step area, non-slip plates and handrails allow technicians to safely work on the machine and allows safe access for the operator. Left-side visibility and ease of entry for the operator have been improved by moving the door pillar back.

The large, multifunctional color monitor does not obscure operator visibility to the surrounding work area. This monitor enables engine oil and coolant levels to be checked from the operator’s seat. The operator no longer has to invest time walking and opening panels to check these vital fluids.

To enhance visibility around the machine, the rear camera has a broadened visual range that allows the operator to see the area right below the counterweight. It is possible to view both the operating status icons and the rear-view monitor display simultaneously.

Intelligence drives productivity

Quarries are increasingly relying on data to track machine and operator performance. Hitachi provides a robust solution with ConSite® Global e-Service. This service tracks performance metrics like idle time, operating time and fuel efficiency, along with location services in real time, and it alerts owners and operators to upcoming maintenance needs. These “predict and prevent” tools help fleet managers maximize machine efficiency, minimize downtime and improve overall performance.