Mine sites are getting serious about decarbonization, and more are exploring electrification as a possible solution to reduce greenhouse gas emissions. Reducing carbon emissions while maintaining productivity is a formidable challenge as mining remains an energy-intensive activity.

For Hitachi Construction Machinery (HCM), the road to zero emissions for today’s mine sites hinges on the efficient use of energy. Electrification and energy management are two key areas of focus that can drastically reduce the carbon footprint of mining machinery. Energy is one of the biggest expenses for mining companies. According to Deloitte, existing mines can reduce their total energy consumption by 15% to 20% through an effective energy management program. New mines can see reductions up to 50% by rethinking the mine with energy management in mind.

Energy management represents a tremendous opportunity for mine sites to increase profitability by reducing energy consumption while cutting emissions and waste. Developing an energy management plan and understanding how energy is consumed on the mine site can help mines achieve sustainability goals. Some of the more progressive mine sites are already moving toward electrification and are exploring renewable power options, such as solar arrays to complement traditional power sources.

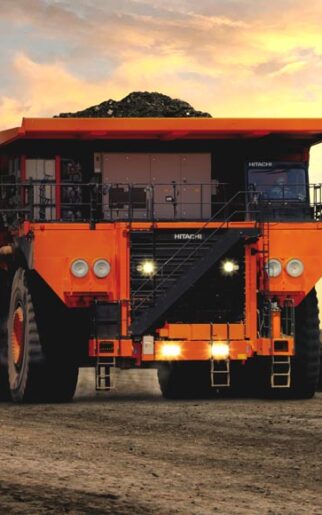

HCM has been a leading proponent of electrification. The company has well-established expertise in the electrification of mine-site equipment with ultra-large hydraulic excavators wired for electric power and AC-drive haul trucks. Electrification can increase the energy efficiency of mining machines. Consider the example of a battery-powered haul truck. Energy can be captured and reused during braking, and energy use can be limited when the vehicle is not traveling. This helps offset activities that consume energy but do not contribute to material movement.

The road to electrification

Traditional trolley technology is one of the most obvious methods to drive a reduction in carbon emissions. HCM has been supplying trolley-assist haul trucks for mining that run on electricity from overhead wires since the 1980s. It is currently an option on all the company’s haul trucks.

In addition to reducing emissions, this technology can increase productivity with faster hill-climbing speeds and reduce wear on traditional diesel engines. While on electric power in trolley mode, the diesel-electric haul truck’s engine idles at 1,200 rpm, directing power only to the auxiliaries and the hydraulic pump — even when the machine is being driven uphill under load. In some applications, electrifying high-demand segments of the haulage route eliminates more than 50% of the emissions.

There’s a future opportunity to replace the diesel-powered AC-drive haul trucks in the trolley system with battery electric haul trucks. The existing trolley infrastructure could be used for charging batteries and providing energy to power the trucks. Because today’s battery technology has limited energy-storage capacity, the success of electrified haulage relies on the ability to quickly move electrical energy from the grid to mobile vehicles.

The battery electric haul truck could use battery power to travel between the trolley, the loading site and the dump site. The trolley would then recharge the battery while simultaneously powering the truck. There are also charging stations in the research-and-development phase. “Putting a battery in the truck isn’t the hard part; it’s making it work in a real mine site,” said Product Manager of Mining Trucks John Schellenberg.

But the benefits of the technology cannot be ignored. A battery electric vehicle (BEV) system is capable of more than 70% efficient use of energy when calculating from ”generation to material moved.” This compares to a standard haul truck that might run at 35% efficiency.

Building on a foundation

HCM continues to develop a BEV haul truck solution that will leverage possible energy-efficiency gains. For HCM, the development of the haulage unit is the easiest part of the equation. The company already has a modern electrified platform that utilizes AC electric drive.

The biggest challenges will be energy storage and management. “Battery solutions have been part of Hitachi Limited’s rail portfolio for more than 10 years, so applying this rail/battery technology from our corporate network to transition HCM’s truck lineup is a natural progression,” said Schellenberg. The company also continues to monitor hydrogen as a pathway to electrification for some mining applications.

While the battery electric haul truck is still a prototype, there are existing electrification strategies that are commercially viable. “I believe that electrification is not only possible with today’s technology, but it can also achieve a better commercial rate of return than conventional techniques in a number of applications,” said Schellenberg.

No one-size-fits-all solutions

Every mine site has its unique challenges, with differing haul lengths, elevation changes and loading and dumping setups. These varying conditions can present challenges for onsite electrification. All the variables must be considered along with the availability and reliability of any “green” energy supplies.

Promoting decarbonization is a major global trend, but it is also critical for the future of mining. Diesel engines may be here for the foreseeable future due to their power density, the flexibility they offer and their widespread availability. But emerging technology and electrification provide opportunities to reduce carbon emissions and start down the path toward net-zero emissions.

Many major HCM mining customers are supporters of the Task Force on Climate-Related Financial Disclosures (TCFD), aiming to decarbonize. HCM will work closely with them to understand their challenges and requirements to reduce carbon-dioxide emissions at their mine sites.

To learn more, contact your local Hitachi Construction Machinery mining expert.