Much of the world’s mining remains energy intensive. Almost every process consumes fossil fuels and the demand for minerals continues to increase as they are vital to the batteries, chips and devices powering the emerging energy transition, which continues to pick up steam. With many large mines adopting environmental, social and governance (ESG) policies, there is a push to find more sustainable mining solutions to meet this growing demand. Some of the world’s largest mining companies are driving toward carbon neutrality and sustainable mining.

One of the first steps most mines can take toward reducing carbon emissions is reducing diesel fuel consumption. Eliminating the diesel engine is not a viable option at this point. “Diesel engines will have a place in mining for some time,” notes John Schellenberg, mining product manager for Hitachi Construction Machinery Co., Ltd (HCM). “Not all regions have the local infrastructure requirements to adopt zero-emission solutions.” Some of the modernized regions with developed infrastructure will be on the leading edge of more sustainable solutions.

Diesel engines may be here for the foreseeable future due to their power density, the flexibility they offer and widespread availability. But emerging technology and electrification provide opportunities to reduce carbon emissions and start down the path toward net-zero emissions.

Electrifying mobile machines, where possible, can have a large environmental impact. According to Creating the zero-carbon mine, an article published by McKinsey & Company, currently 40% to 50% of carbon dioxide emissions come from diesel fuel used in mobile equipment, while another 30% to 35% come from the production of nonrenewable electricity. Emissions vary widely across the broad range of mine sites, but haul trucks are responsible for most of them. This presents a large opportunity.

Electrification provides a path to more sustainable mining

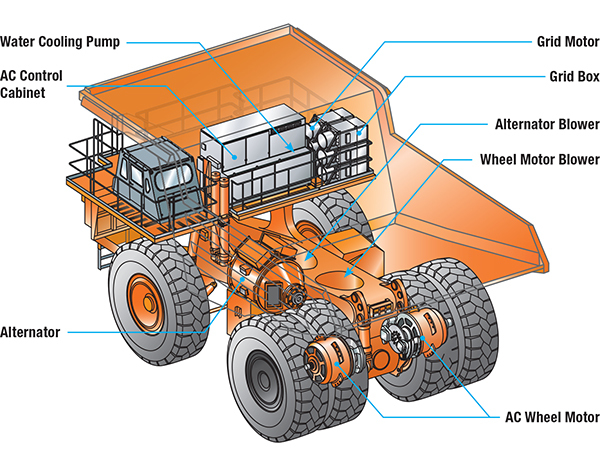

In the mining industry, HCM continues its efforts in developing solutions to reduce fuel consumption, and the resulting carbon dioxide emissions, in its mining equipment while continuing to research and develop cleaner technologies. The company has well-established expertise in the electrification of mine-site equipment with ultra-large hydraulic excavators wired for electric power and AC-drive haul trucks.

HCM announced a collaboration with ABB Ltd., a Swiss company with strengths in electrification, automation and digital technologies for mining machinery. ABB has experience throughout the mining process, including mining equipment management systems. Together, HCM and ABB are working to achieve net-zero emissions, the goal being to offer innovative products to improve the efficiency and scalability of mine sites through a fusion of solutions from both companies. One of the first joint projects is the development of a battery-electric haul truck that will use trolley-assist to charge onboard batteries while simultaneously providing energy to power the truck.

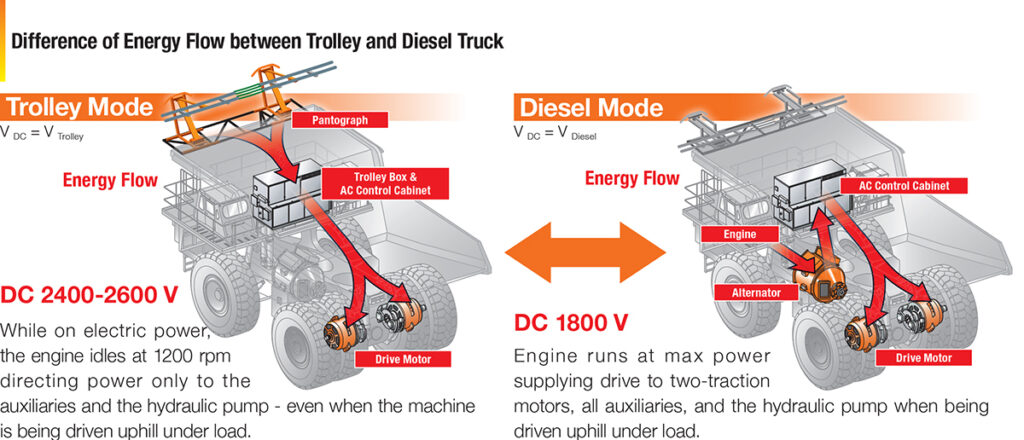

HCM has been supplying trolley-assist haul trucks for mining that run on electricity from overhead wires since the 1980s. It is currently an option on all the company’s haul trucks. The trolley-assist increases productivity by providing higher speeds during loaded hill-climbing, in addition to reducing fuel consumption and increasing engine life.

According to ABB, mining trucks regularly carry 3,000 to 5,000 liters (792.52 to 1,320.86 gallons) of diesel and consume 300 to 400 liters per hour (79.25 to 105.67 gallons per hour) while traveling up a 17-kilometer (10.56-mile) ramp in half an hour. By going electric, the vehicles on-trolley only use around 30 to 50 liters an hour (7.93 to 13.21 gallons per hour), saving as much as 350 liters per hour (92.46 gallons per hour).

While this sounds impressive, the battery-electric haul truck would provide an alternate solution to the diesel engine. “Battery solutions have been part of Hitachi Limited’s rail portfolio for more than 10 years, so applying this rail/battery technology from our corporate network to transition HCM’s truck lineup is a natural progression,” says Schellenberg. Since the truck already uses AC electric drive, the biggest challenges will be energy storage and management.

While the battery-electric haul truck is still a prototype, there are existing electrification strategies that are commercially viable. “I believe that electrification is not only possible with today’s technology, but it can also achieve a better commercial rate of return than conventional techniques in a number of applications,” says Schellenberg.

The diesel/electric truck technology simplifies electrification since the electric drive system technology is already on the truck.

Expanding beyond machinery

HCM acknowledges that achieving the goal of net-zero emissions in mining operations requires a broader approach beyond simply electrifying its product lineup.

On the journey to net-zero emissions, mine sites will not only need to focus on fuel consumption and efficiency but also on digitization and automation. In recent years, HCM has expanded its business by investing in technology software and hardware solutions. In 2009, HCM purchased Wenco International Mining Systems Ltd (Wenco), a leading producer of fleet management systems and technology to improve mine operation efficiency.

In January 2022, HCM announced the launch of ConSite® Mine. It incorporates internet of things (IoT) technology and artificial intelligence (AI) to provide data that can improve operating efficiency which may contribute to reducing carbon dioxide emissions. It remotely monitors mining machines 24/7 giving insights into machine performance and operability. HCM developed this technology to help dealers and customers predict maintenance issues before they occur with detailed alerts and reports provided via email and on the web-based ConSite Mine dashboard. And with future upgrades, will expand its capabilities to connect to Wenco’s cloud-based “ReadyLine” system to provide greater integrated system management solutions across mine operations.

Promoting decarbonization is a major global trend but is also critical for the future of mining. Many major HCM mining customers are Task Force on Climate-Related Financial Disclosures (TCFD) supporters aiming to decarbonize. HCM will work closely with them to understand their challenges and requirements to reduce carbon dioxide emissions at their mine sites.

Hitachi Construction Machinery Co., Ltd., headquartered in Tokyo, Japan, manufactures hydraulic excavators, shovels, wheel loaders and haul trucks for the mining market. Hitachi Construction Machinery Americas Inc. (HCMA), with a U.S. Corporate office and campus in Newnan, Georgia, distributes and supports mining equipment throughout North America and Latin America. For more information, please visit hitachicm.us/mining.