FOCUS magazine, first published in 2003, was inspired by a team of Kawasaki dealer personnel, satisfied customers and an eager Kawasaki marketing team who wanted to bring compelling stories, tips and industry news to wheel loader users throughout North America. Fifteen years later, our goals remain the same, our focus renewed with the global vision of Hitachi.

FOCUS magazine, first published in 2003, was inspired by a team of Kawasaki dealer personnel, satisfied customers and an eager Kawasaki marketing team who wanted to bring compelling stories, tips and industry news to wheel loader users throughout North America. Fifteen years later, our goals remain the same, our focus renewed with the global vision of Hitachi.

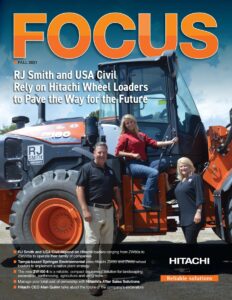

With 19 wheel loaders in a range of sizes in their fleet, the machines that keep the six companies that make up RJ Smith and USA Civil working and growing also ensure the family businesses work seamlessly across companies to deliver any customer solution. Richard Smith says the business is attracting young, ambitious people, and they are developing the next generation of managers. Check out their approach to using Hitachi loaders to benefit their people and their customers.

With a mindset toward educating the Tampa area about the value and benefits of native plants, Troy Springer of landscaping firm Springer Environmental leverages his relationship with Great Southern Equipment to share his passion. Developing a smart rental strategy, Springer partners with the dealer to use ZW50 and ZW80 wheel loaders to carry and place tall pines and sable palms. Check out how Hitachi simplifies the task.

Advanced technology, superior comfort, enhanced design and more are at the forefront of the new ZW100-6 wheel loader. This compact yet powerful loader is designed to handle a range of applications from landscaping; heavy construction; excavation work; water, sewer and pipeline construction; highway and road construction; and agricultural work. Read more about the ZW100-6, which features a Tier 4 Final certified engine that does not require a DPF, reducing fuel consumption and maintenance costs.

Managing costs is more streamlined than ever with Hitachi’s After Sales Solutions. Modernize, upgrade, and renew aging equipment to manage their total cost of ownership. Discover how After Sales Solutions can make a difference in your bottom line.

After more than three decades of partnership, Hitachi and John Deere will end their joint venture manufacturing excavators for North and South America in early 2022. Beginning Spring 2022, Hitachi will manufacture and distribute its own excavators. Alan Quinn, CEO, Hitachi Construction Machinery Americas Inc., explains what the new venture means for the company.

CLICK HERE TO DOWNLOAD A PDF OF THE HITACHI FOCUS MAGAZINE, FALL 2021 EDITION

John Deere and Hitachi are dissolving their joint venture of more than 30 years for manufacturing excavators in North and South America.

After February 28, 2022, Hitachi Construction Machinery Americas Inc. will stand on its own for distribution and sales of its brand excavators on the two continents. Hitachi plans to manufacture all its excavators, as well as its wheel loaders and mining equipment, in Japan, and then import them to the North and South American markets.

Hitachi Construction Machinery Americas Inc. also plans to introduce new equipment to the markets, which the company says will have “cutting-edge technologies that increase efficiency and safety while lowering total cost of ownership.” Those technologies include advanced hydraulic and safety systems, “internet of things” services and telematics.

The two companies own a joint plant in Kernersville, N.C., where Deere and Hitachi hydraulic excavators of 13 to 47 metric tons are produced. They also own plants in British Columbia, Canada and Brazil.

Hitachi Construction Machinery Americas Inc. CEO Alan Quinn said in an interview with Equipment World that Deere will purchase the factories. He added that parent company Hitachi Construction Machinery and Deere have entered into a supply agreement in which Hitachi will continue to provide the excavator kits for Deere to assemble excavators after February 28.

Hitachi Construction Machinery Americas Inc. plans to keep its regional headquarters in Newnan, Georgia, where Quinn says it also plans to add 75 to 80 employees. About 60 of those positions will be local hires, he said. Positions will include sales, distribution, dealer service, marketing and more – across the board, he says. The company is also seeking a location for a parts distribution center, which Quinn said would be about 400,000 square feet and have about $150 million in parts stock. Hitachi Construction Machinery Americas Inc. will operate as a wholly owned subsidiary of Hitachi Construction Machinery, based in Japan.

Hitachi Construction Machinery Loaders America, formed in 2017 after the company purchased KCM wheel loaders, will also be part of the Hitachi Construction Machinery Americas Inc. umbrella, and “Loader” will be dropped from the name, Quinn said.

Deere and Hitachi began forging a supply relationship in the 1960s. They formed the Deere-Hitachi Construction Corporation in Kernersville in 1988. In 1998, they started a “Base USA” strategy in which the same models were built for both brands at the plant. The joint venture later branched out with an excavator plant in Canada and a forestry excavator factory in Brazil.

For Hitachi, the collaboration gave it Deere’s well-established dealer and distribution network, and Deere benefited from Hitachi’s design and manufacturing expertise. Hitachi is one of the top-selling excavator manufacturers in the world. It started mass production of cable-operated shovels in 1950, and in 1965 produced the first hydraulic excavator in Japan with entirely Japanese technologies, according to the company’s history.

Quinn joined Hitachi in 2017, and he says the goal in the ensuing years has been to position Hitachi to build its brand in the Americas to match its global standing. Hitachi has a base of 60 wheel loader dealerships in the U.S. Quinn said the company is looking for an opportunity to revolutionize distribution in the construction equipment industry.

“I think that we’re in a perfect place to really be one of those disruptors in innovation and really capture some of the new ways of doing business and looking after our customers,” he said. As for moving production to Japan, Quinn said that today’s machines are more standardized than they were 10 to 15 years ago.

“Today, the markets have become a lot more competitive. The technology is higher, but also the machines are more standardized,” he says. “And that’s really made it a little bit more cost effective and actually more customer friendly for us to bring it directly from Japan.”

As for the new excavators, he said Hitachi will be able to bring all its technologies and other features to differentiate its machines in the Americas.

“We get to make sure that all the equipment we sell has all of the technology available at Hitachi today,” he said. “So we’re going to differentiate the products that we bring by incorporating everything that we have to offer.”

Hitachi said new equipment would be introduced in the Americas in Spring 2022.

Quinn noted that the company’s wheel loaders and mining excavators and trucks are part of the new Hitachi Construction Machinery Americas Inc., and that includes South American markets as well. Quinn said a separate mining division would be housed at the Newnan headquarters. Company goals also include increasing the company’s rental and used equipment market presence and global usage of its ConSite telematics services.

This story first appears in Hitachi’s Fall 2021 issue of FOCUS magazine. Download the magazine here.

Hitachi’s After Sales Solutions provide you with tools you need to manage your total cost of ownership quickly and easily, whenever and wherever you are.

Optimize your operation with Hitachi’s After Sales Solutions, which not only provide customers with the ability to extend the life cycle of machines, but also modernize, upgrade, and renew aging equipment to manage their total cost of ownership.

Focusing on Parts, Support Services, ConSite, Global E-Service, Service Contracts, Remanufacturing and Training, Hitachi’s After Sales Solutions deliver improved productivity, higher profitability and cost-efficiency.

Parts:

Whether you require Hitachi Genuine Parts that allow machines to work longer with low running and maintenance costs, or Performance Parts that deliver durability, performance and extended life under demanding conditions, Hitachi’s After Sales Solutions have what you need. The U.S.-based parts warehouse has a wide range of parts available to suit your demands.

Support Services:

Keeping your loaders running efficiently and productively helps you build your bottom line. After Sales Solutions includes maintenance and repair contracts that provide hands-on experience supporting not only Hitachi wheel loaders, but also Kawasaki and KCM legacy loaders.

ConSite:

Hitachi’s ConSite, an asset management suite that manages loader performance and productivity, is the perfect solution to help you hit your goals. Tracking performance metrics such as operating and idle time and fuel efficiency, ConSite helps users adhere to maintenance schedules. The platform is user-friendly and ensures you have access to the data you need to manage your fleet, whether one machine or several.

Global e-Service:

With advanced asset management in a quick, customizable dashboard, you can not only manage your fleet, but also plan service proactively. You’ll be able to group machines, view current or historical data, view diagnostics reports and receive monthly reminders. Reviewing the status of your fleet has never been simpler.

Remanufacturing:

After Sales Solutions includes genuine factory remanufacturing that keeps machines in “original” condition through their next life. The Reman Center, located in Newnan, Georgia, ensures components are built to Hitachi specs by trained specialized technicians and thoroughly tested using the same criteria the machines are running in the field. These cost-efficient alternatives to new components are direct shipped where they are needed, and backed by the Hitachi one-year, 1,500- hour Reman Warranty.

Training:

Stay up to date on current practices, processes, and procedures focused on keeping your machines running efficiently with onsite or online training programs. These After Sales Solutions will teach you to save time when troubleshooting, solve problems using your mobile devices and experience real-time solutions when you need them.

Use Hitachi’s technology programs and apps to:

- Extend equipment life

- Manage preventative maintenance, machine efficiency and operator productivity

- Manage operating costs, fuel consumption and operator efficiency in the field Want more information on the Hitachi After Sales Solutions? Contact your Hitachi dealer or learn more information.

This story first appears in Hitachi’s Fall 2021 issue of FOCUS magazine. Download the magazine here.

Troy Springer’s love of native plants has fueled his landscape company’s growth. Smart use of Hitachi rentals helped him do more.

Troy Springer’s love of native plants has fueled his landscape company’s growth. Smart use of Hitachi rentals helped him do more.

Landscaping and a love of native plants came to Troy Springer naturally. “I’ve always been interested in wildlife and nature,” says the Tampa, Florida-area native.

Early on, Springer worked for a traditional landscaping company, but like many successful people, he quickly realized he needed to carve his own path to be satisfied.

“I almost got out of landscaping because I felt like what I was doing for other companies was harmful,” Springer says. In particular, he disliked the practice of many traditional landscapers who use plants that may be appealing visually but aren’t native to the area where they are planted. Non-native plants can do one of two things, he says: they can become invasive, or they can fail.

“Then I discovered the native plant societies and got involved,” Springer says. “I studied relentlessly, and I started practicing it, and I got better and better at it. Now I have a pretty good reputation.”

That reputation includes serving as a former chapter president of the Florida Native Plant Society and producing a conference for them. Springer is also the secretary and on the board of the Florida Association of Native Nurseries, the nation’s largest professional native plant network.

Design-build

Today, Springer Environmental has eight employees, working as three different crews. The company’s work is primarily design-build for high-end residential landscaping customers, but they also do some commercial work, such as the landscaping for a new City of Tampa park.

“They needed a native plant specialist, and I was the only game in town,” Springer says. “I have done work with some developers, but I’m more of a custom-build guy because I design my own landscapes. I typically target homeowners directly.”

Springer’s shop sits on a few acres that he is developing into a nursery, where he can demonstrate to customers the beauty and variety of native plants. “Retail is a good fit for bringing in potential customers,” he says. “They can come in and see the plants and some of the work we do.”

Big machine for small company

Springer owns a handful of small tractors used to carry plants in containers and move soil and other materials. But as the size and scope of the landscapes he created increased, Springer knew he would need a bigger machine.

Smaller machines didn’t have the horse power or the weight and balance to carry sable palms and pines ranging anywhere from 15 to 30 feet tall. Some weigh more than a ton. Backhoes and skid steers were too hard on turf, and even compact track loaders didn’t have the weight to counterbalance these big trees.

And planting these trees involves more than just dropping them in a hole. With their long trunks, these trees must be positioned with the trunk perfectly vertical from all angles. The tree is often initially placed and then picked up and repositioned multiple times as Springer and his crewmembers evaluate the line of the trunk. If necessary, the hole may be dug a little deeper or more to one side to get a perfectly plumb tree.

But the company didn’t have the cash flow to support the purchase of a bigger machine. The solution was to rent Hitachi ZW50 and ZW80 wheel load-ers when the job requires it, which is typically several times a year. Springer outfits his rental units with a tree boom, and with the articulating front end of the wheel loader, he can carry and fine tune the placement of the tree with minimal movement of the machine and minimal disturbance of the turf.

Racing connections

Steve Tuton, salesman for Great Southern Equipment, first met Springer thanks to a shared hobby: racing Mazda Miata sports cars.

Steve Tuton, salesman for Great Southern Equipment, first met Springer thanks to a shared hobby: racing Mazda Miata sports cars.

“I quickly determined his business overlapped with mine and that he could be an occasional user of some of our equipment,” Tuton says.

“Kawasaki didn’t have the small loaders back then, but when the Hitachi loaders became available, I made sure he knew about them.”

The relationship turned out to be mutually beneficial. “Troy introduced me to many other members of our native plant societies, including owners of tree nurseries and landscape tree installers,” Tuton says. As a result, Great Southern Equipment started exhibiting in the local shows for these landscapers and tree growers, he says.

Great Southern Equipment doesn’t do a lot of short-term rentals, but when the machines are available and the customer is known to take care of the equipment, Tuton says they are happy to help. Business owners like Springer will often arrange their schedules so they can do multiple jobs in consecutive days and rent the machine for a whole week to get the most out of it, he says.

“None of the small operators are unimportant to us,” Tuton says. “They all matter. Many companies that were smaller when I started 20 years ago are good-sized companies now. If you spend the time to understand their needs and take care of them, they will keep doing business with you as they grow.”

The old Florida look

Springer’s passion for landscaping and native plants is infectious. “I struggled with this business for years because I had this dream of doing something really good for this state, but we’re just now starting to make an impact,” he says. “Ten or 15 years ago, people thought I was crazy to be planting pine trees and palmettos and putting wildflowers in your yard. But they don’t think it’s crazy anymore. It’s amazing how it has exploded in popularity. Our sales have grown significantly.” A recent photo posted on the company’s Facebook page got nearly 1,750 likes, he says.

Springer’s goal is more than just nice-looking yards and landscapes. As Florida’s population continues to boom, residents have become conscious of its unique heritage and culture. Newcomers and old timers alike have rediscovered what Springer calls the “old Florida,” one of lush gardens and crystal-clear springs. But with more people, environmental pressures increase. Native plants not only help achieve the old Florida look, but maintain it by being the right environmental choice, too.

In a climate with a year-round growing season, invasive and non-native plants can run rampant, choking out native plants, clogging waterways and wreaking havoc on what should be a well-balanced and sustainable ecosystem. Native plants are not only better adapted to the climate, but they provide forage and sustenance for everything from birds and butterflies to the Florida black bear as well.

“In Florida there are so many people coming here, we try to be mindful of quality construction and quality landscaping,” Springer says. “If you can make money improving the quality of the environment, that is a major step in having a higher quality society. It’s just good business.”

This story first appears in Hitachi’s Fall 2021 issue of FOCUS magazine. Download the magazine here.

It’s rare to find a dad who gives his daughter Sun Tzu’s “The Art of War” to read rather than the usual teen fluff, but Richard and Monique Smith are no ordinary parents. And this is no ordinary family.

As soon as their daughter Savannah was old enough, she was working and learning the difference aspects of her parents’ Chesterfield, Virginia, companies. She’s grown from sweeping the floors, taking out the trash, and weed eating, to now getting new experiences in building and interior design. Their younger daughters, Sheyenne (13) and Sheridan (9) are headed enthusiastically down that same path. “Balance and income statements are a part of our childrens’ growing up,” says Richard.

In 1995 Richard started his first company with the purchase of a single dump truck and hauled clay during the day, fly ash at night. Whenever a client asked if he could do more, Richard’s answer was always “no problem.” And if necessary, he proceeded to acquire any equipment, knowledge or personnel he needed.

Monique and Richard met in 1996 and soon after, Monique ran the books for the company. But rather than settle into the typical roles where the husband runs field operations and the wife runs the office, Richard and Monique had a better idea. Monique had grown up in a construction family. She not only knew how to keep the books, she knew the equipment, the manpower needs, and how jobs operated. With the background Monique had established, she identified a need to diversify the company into different entities. She is now the CEO and 100% owner of several of the companies.

Today this family of companies includes RJ Smith Construction, RJ Smith Demolition and RJ Smith General Contracting, all run by Richard. Monique owns and operates USA Civil and USA Iron and Metal. Savannah is the CEO of USA Materials. All together the network of companies offer demolition, environmental services, site work and infrastructure, utility infrastructure, trucking, general contracting, emergency services and interstate snow removal.

Each company is vertically integrated and has a distinct specialty and focus, but a single job may involve several entities—a strategy that goes back to finding a solution for every customer request. For example, when the demolition company takes down a building, they can use USA Materials to crush and screen the concrete, which will be sold retail or used as aggregate in one of USA Civil’s projects. The rebar and metal extracted from the demolition will be, packaged and sold by USA Iron and Metal. And if you need a new commercial building on the site, that’s where RJ Smith Construction and General Contracting step up to the plate. USA Civil does a lot of work building infrastructure for the grid and energy companies but can tap into equipment, people or expertise from one of the other divisions when necessary.

Women owned advantages

Women owned advantages

Having two women in ownership naturally attracts other talented women who might be hesitant to work in a male-dominated business and sets the bar at a new level. “We’ve always been taught that you attract what you put out,” says Savannah. “I think entrepreneurial people are attracted to a positive environment. That’s why we don’t have a problem finding good people, because good people want to be here,” she says. “In fact, most of the company’s divisions are run by women and women make up about 20 percent of the workforce,” says Monique. “There are many different areas they can get involved with if they keep an open mind because it’s not just grit work. We have a lot of women doing a lot of different things,” she says.

As an example, Monique cites Zoe, the daughter of Jody, vice president of construction for the last 17 years. “Zoe came on board, and in one year what she’s done is impressive. We put her in charge of the two wedding venues we are building, and she is handling it extraordinarily. I don’t have to push her. She is just on it. And she’s young, right out of college, managing big, multi-million-dollar facilities with me from start to finish.”

“We like to give the employee the opportunity to grow and make decisions,” says Monique. “They start from the bottom and are then able to grow and develop into their full potential.”

Unlike many construction companies, USA and RJ Smith Companies have no problem attracting young, ambitious people. “If you look at our demographics, it is awesome how many young people we have,” says Richard. “They all started at the bottom with high-intensity labor, but we are creating the next generation of managers.”

Like-minded dealer

The idea that good people enjoy working together extends to more than just the employees of the USA and RJ Smith Companies—most notably to its dealer for excavators, cranes and wheel loaders— Link-Belt Mid-Atlantic.

In 2018, prior to the start of this relationship, the USA and RJ Smith companies had worked almost exclusively with a dealer of another brand of equipment. All combined, the various entities owned a fleet of about 125 pieces of equipment, including loaders, dozers, excavators, skid steers, rollers and GPS-enabled units. “Hitachi construction equipment, specifically the loaders, seemed to be the superior product,” said Richard. “We were getting more bang for our buck, and we try to buy the right pieces so we can take care of our customers.”

But when it comes to vendors, a good machine is not enough. Lots of OEMs make good machines, but Richard says he also looks for dealers (and for that matter, customers) who share his passion for excellence—”iron sharpening iron.” That’s why the sale of one Hitachi loader in 2018 turned into the acquisition of 19 additional Hitachi loaders from 2019 to 2021, ranging in size from the smallest ZW80 to the ZW220.

“Link Belt Mid-Atlantic has a similar team mindset,” says Richard. “That’s one of the reasons everybody meshes well, whether it’s the president or the general manager or the mechanic. It’s almost like we’re talking to somebody at one of our companies.”

And it’s not just a matter of good feelings, but smart business. “You have to have great teams from top to bottom,” says Richard. “A weak vendor can take you out. The reason we work with Chris Beal (their Hitachi construction equipment salesman at Mid-Atlantic) and his team is that they take care of our business. And they also just happen to sell a really good wheel loader.”

“If we can present them with a good package, it allows them to make better decisions moving forward,” says Beal. “What’s nice about working with companies like RJ Smith and USA Civil is that they help us become better. Their partnership has helped us grow.”

Perhaps the greatest testament to the strength of the relationship between the USA and RJ Smith Companies and Link-Belt Mid-Atlantic is that the dealer insisted that RJ Smith build their new 17,000 square foot facility. The reason was simple: the dealership knows that RJ Smith and USA Civil would deliver outstanding results. “We got a perfect, grade-A, top-of-the-line facility,” says Beal.

Upgrading to Hitachi Construction Equipment

“Richard and Monique gave us the opportunity to show the ZW180-6, which is a little bigger than the old Kawasaki 150,” says Beal. “But given the type of work they do it was more productive for about the same price they were getting smaller machines for. That’s how they ended up with 19 Hitachi loaders.”

“The bulk of our loader fleet is in the Hitachi ZW180-size,” says Jeremy Setelin, vice-president of USA Civil. “We use the big loaders for materials processing. They are all equipped with Loadrite scales from Trimble, and they’re used primarily to push around big heavy concrete chunks all day long.”

In the Chesterfield concrete processing facility, the concrete demolition waste is crushed and screened right next to USA Iron and Metal. Rebar and other debris is extracted from the rubble and operators use the ZW80s to load it into Gaylord boxes that when full weigh up to 2,500 pounds.

Along with the wheel loaders, the USA and RJ Smith companies have 22 excavators in the field. “That’s a lot of equipment from one dealer, but they do a really good job servicing the equipment and communicating what our needs are for the future, so we don’t have any emergencies,” says Setelin. The ease of working with Sumitomo financing is another reason USA and RJ Smith companies chose the Hitachi loaders, says Setelin.

Given the multiple and sometimes over-lapping jobs of the different USA and RJ Smith entities, a wheel loader that could be useful in wide range of applications was desired. “We are not going to buy a machine for just one thing. If the materials business were to stop tomorrow, we could take those wheel loaders and put them to work, elsewhere.” says Setelin.

In 2020 Setelin also integrated the Hitachi ConSite telematics feed into a Trimble Pulse telematics program that embraces all the company’s construction and trucking assets. The telematics allow anybody with access and a smart phone to track the equipment, schedule maintenance and communicate with the dealer when there is an emergency.

“With the telematics, I don’t have to keep track of so many things in my head and the operators don’t have to wait for their foreman to make equipment decisions on site,” Setelin says. “It has empowered our relationships with vendors and in the end makes my job a lot easier,” he says.

Ultimately the choice came down to performance and operator preference.

“The operators wanted something that is more comfortable and responsive,” says Beal. “With the Hitachis you don’t have a large, complicated computer screen. You don’t have to punch a bunch of buttons or run through a lot of scenarios. You can run everything with your two hands on the joysticks. It’s not overbuilt or over-complicated,” he says.

Radical truth

To keep this ambitious group of people and this diverse range of businesses doing their best work requires what Richard calls a “radical truth” environment. “You only need to open the Bible to learn our value system,” he says. “We will tell you exactly how we feel. That can make you uncomfortable, or it can make you better. If people know where we stand, they can make better decisions for themselves. Some people are attracted to that, and some are not. But you don’t have to micro-manage the ones who are attracted to that. You can macro-manage them, and we’re a macro-manage type of company.”

“It is important that they know what kind of company they’re coming to work for,” says Monique. “We’re very team-oriented and we rely heavily on each other, because we have multiple companies, one person doesn’t have to necessarily do one thing. They’re constantly changing hats.”

“You could drive a truck, and if you want a career change to become a superintendent in the general contracting division, that happens here,” Richard says. “You don’t want to lose that employee you spent 20 years developing, so you give them the opportunity to switch jobs within the same culture. A lot of organizations can’t do that.

“Here employees have multiple opportunities. Everybody is critical to every operation and cross-trained as much as possible. If you build a company around that, you don’t lose customers and you don’t lose employees,” says Richard. “Larger companies hire more people to perform smaller roles. We hire fewer people who can do more.”

Safety and environment

A good portion of the companies’ work comes from federal and state governments as well as other infrastructure clients. These entities place safety and environmental protection on the top of their priority list, as the USA and RJ Smith companies do as well. The companies in the RJ Smith fold have an experience modification rate (EMR) of 0.72, which, Setelin says, is almost unheard of in such a wide-ranging scope of services. USA Civil follows suit with a strong EMR of 0.81.

Each company has a diligent safety team, daily toolbox talks, and twice a year conducts their own safety summits. Because the companies see everyone as a safety officer, this time allows for concerns to be voiced and annual training requirements to be met. Everyone is trained in OSHA 10 requirements, and most supervisors go through OSHA 30 training. Before any of the company truck drivers hit the road alone, they spend their first week riding with a veteran truck driver.

As for environmental protections, the crews are all trained and have certificates in erosion control. Some staff are also trained and certified in the more rigorous Virginia DOT and federal government standards. “We want that integrated throughout the organization, so that we’re confident in whoever goes out to do the work,” says Richard.

God, Family, Country

The family and companies’ fervor to be involved in their community has manifested into the largest flag in Virginia, located just seconds from the USA Companies headquarters. The flag soars at 212 feet, representing their following of the “extra degree” philosophy, and can be seen from I-95 and Route 288. The flag is located at Unity Park and has become a visible symbol of unity and national values in the area.

The “extra degree” philosophy states that at 211-degrees Fahrenheit, water is merely hot. “At 212 degrees it turns to steam, and steam is what drives locomotives,” says Richard. This philosophy is based on the best-selling book 212, The Extra Degree, by Sam Parker and Mac Anderson.

Their family values of God, Family, and Country flow deeply. In a speech Savannah gave at a local event, she showcases their support of community, especially the military and first responders, by stating, “These brave men and women that we stand behind and love are the reason it is possible for our nation to prosper independently and stand securely. Many things change, but one thing that will always stay true is the fact that we are the UNITED States. Our desire to unify and propel forward together is, and will always be, stronger than our faults and divisions because there is only one nation under God.”

This story first appears in Hitachi’s Fall 2021 issue of FOCUS magazine. Download the magazine here.

A reliable, compact equipment solution for landscaping, excavation, earthmoving, agriculture and utility work

Hitachi’s ZW100-6 builds on the company’s reputation for top-flight wheel loaders with improved loading efficiency, easy maintenance, intuitive controls and a cab designed to keep operators safe throughout their work day.

Hitachi’s ZW100-6 builds on the company’s reputation for top-flight wheel loaders with improved loading efficiency, easy maintenance, intuitive controls and a cab designed to keep operators safe throughout their work day.

With the introduction of the ZW100-6 compact model, Hitachi continues to expand its ZW-6 wheel loaders in North America. Developed for use in a wide variety of applications — including landscaping; excavation work; water, sewer and pipeline construction; highway and road construction; and agricultural work — the small yet powerful ZW100-6 wheel loader features an operating weight of 17,042 pounds (7,730 kg), bucket capacity of 1.4 yd³ (1.1 m³) and a 101-horsepower (74-kW) Tier 4 Final engine.

This new ZW-6 model also boasts a spacious cab with 360-degree visibility, ride control and onboard technology that enhances operator comfort and increases productivity with quick and efficient cycle times.

Advanced technology developed by Hitachi impacts everything from the wheel loader’s environmental performance to the comfort and safety of its operator to its cost of ownership. For example, each ZW-6 wheel loader comes equipped with a diesel after treatment system that eliminates the hassle and costs associated with diesel particulate filter (DPF) systems, plus onboard technology and an advanced telematics system to help contractors better manage their fleet and operating expenses. This technology-led approach enables Hitachi to meet the evolving needs of the construction industry while improving its customers’ experience with this new generation of wheel loaders.

Smooth operation

The new ZW100-6 is easy to maneuver thanks to the hydrostatic transmission control system. The operator can choose between two work modes according to the task and terrain and experience a smooth transition between speeds. Also, the ride control feature on this model minimizes machine pitching for a smoother ride and to reduce bucket material spillage.

The oscillating rear axle on the ZW100-6 gives it more stability and traction, especially on uneven ground, than loaders with a fixed axle. For higher efficiency when working in snowy, slippery or muddy conditions, the traction control system on the ZW100-6 helps avoid tire slippage and, ultimately, prevents wear and fuel waste while lowering running costs. This feature makes this new Hitachi model highly effective for light applications.

Powerful performance

Powerful performance

This new ZW-6 model is equipped with a Tier 4 Final certified engine that does not require a DPF, which reduces fuel consumption and maintenance costs. For example, the ZW100-6 demonstrates greater fuel efficiency than the previous model during V-shape loading and load-and-carry operations. This results in considerable savings for running costs. And for efficient flexibility, it has a quick power switch that can increase engine output when more power is instantly required or when driving uphill.

Superior visibility

The 360-degree panoramic visibility from the cab of the ZW100-6 is an industry-leading safety feature that also creates a comfortable, productive working environment. An optional rearview cam-era also contributes to excellent all-round visibility and safety on the job site.

In addition, the muffler and air intake on this new ZW-6 model have been repositioned, giving the machine a sleek and modern curved-hood design, and are aligned to improve the rearview visibility from the cab to further enhance safety on a variety of job sites.

Enhanced cab environment

The ZW100-6’s cab provides a quiet and comfortable working environment for operators. Sound insulation has been improved in the cab to significantly reduce noise levels. The low-noise engine also results in a quieter performance, which makes it suitable for working in urban areas.

The spacious cab design includes several storage compartments that provide quick access to important items, such as PPE, phones and paperwork, to further increase operators’ efficiency and safety while operating this new ZW-6 machine.

Updated design

Heavy-duty axles and a reinforced front frame, both designed in-house, have been incorporated into the new Hitachi ZW100-6 wheel loader to improve the machine’s durability. And for added protection, an optional belly guard protects the machine powertrain and driveshaft from potential damage caused by materials on the ground.

The ZW100-6 design includes wide, easy-to-open engine covers that offer quick, convenient access to all of the machine’s critical components. This feature enables operators to conduct daily machine inspections safely and quickly from the ground, ensuring routine maintenance can be completed easily for reliable performance.

Remote monitoring

This new model comes with Global e-Service, which allows equipment owners to monitor their Hitachi ZW100-6 wheel loader remotely via Owner’s Site, and ConSite, Hitachi’s full data toolkit with a suite of apps for managing loader performance and productivity. ConSite tracks performance metrics like idle time, operating time and fuel efficiency along with location services in real-time, and it alerts owners and operators to upcoming maintenance needs. These “Predict and Prevent” tools help fleet managers maximize machine efficiency, minimize downtime and improve overall performance. After adding the new ZW100-6, the Hitachi ZW-6 wheel loader lineup now includes 15 models.

This story first appears in Hitachi’s Fall 2021 issue of FOCUS magazine. Download the magazine here.

Hitachi Construction Machinery Americas Inc. (HCMA) announces today that the first medium-sized Hitachi ZX210LC-6 utility hydraulic excavator, built for the North American market, has shipped from Hitachi Construction Machinery Tsuchiura Works (Tsuchiura, Ibaraki Prefecture, Japan). The ZX210LC-6 excavator is the first of many Hitachi-built and branded machines soon to be available throughout North America and Latin America. With the joint venture dissolution between Hitachi Construction Machinery Group and Deere & Company, announced earlier this year, HCMA is committed to independently developing and deploying the latest product advancements, technologies, and services throughout the region.

To celebrate this important milestone for Hitachi and its customers, the team in Japan responsible for developing and building this first excavator unit gathered to give it a proper sendoff. Draped across the machine is a banner with the phrase “Empowering the Americas — The Lineup Grows More Powerful.” This message signifies HCMA’s commitment to its customers moving into the future.

Since 1965, with the introduction of the Hitachi UH03, Japan’s first hydraulic excavator, Hitachi hydraulic excavators have been a flagship product of the Hitachi Construction Machinery portfolio. With a range of models available to meet customers’ specific requirements, these machines excel at leveling and forming work for large-scale residential land and the development of social infrastructure for roads, railways and riverways.

Hitachi utility excavators available in the Americas, including the ZX210LC-6 model, are equipped with state-of-the-art hydraulic systems that feature high-efficiency AERIAL ANGLE® technology to help improve worksite safety and the brand’s ConSite® OIL service solution. These machines are designed to help contractors in the Americas maintain the quality of work amid labor shortages and the decline of experienced operators, as well as to contribute to improved productivity and safe operation.

Local sales for the latest Hitachi-built line of equipment will start in North America in March 2022.

Hitachi Equipment Starring In Discovery’s Channel’s “Gold Rush”

Heading into its 13th season on the Discovery Channel, “Gold Rush” hails the return of Todd Hoffman, after a 3-year absence, to take another shot at striking it rich. Co-starring with Hoffman’s family and veteran crew, you’ll see Hitachi equipment working hard to make Hoffman’s dreams a reality.

The action is based north of Nome, Alaska, where the Arctic climate and harsh landscape are a tough test for both man (and woman) and machine. But our Hitachi equipment is up for the challenge. As Todd says, “No guts, no glory!”

Watch for the initial 10-show run in January 2022, with a full season to follow.

Get a preview of the new Gold Rush, here:

https://www.discovery.com/shows/hoffman-family-gold/articles/todd-hoffman-returns-to-gold-mining

HCMA has introduced the latest addition to its line of compact loaders with the ZW100-6. Featuring the Dash-6 range of engineering upgrades and advanced technologies, the ZW100 is the largest machine in Hitachi’s compact lineup The new ZW100-6 is equipped with industry-leading technology features that cover everything from environmental performance to operator comfort and safety to the machine’s Total Cost of Ownership. Highlights include Tier 4F with DPF-free emissions control, ConSite fleet management system, operator-friendly ride control and “the best visibility in the business.”

For additional details, see the report from Equipment Today magazine, here.

The ZW220-6 wheel loader has been named one of the Contractors’ Top 50 New Products of 2021* by Equipment Today, the nationally recognized equipment magazine serving commercial construction contractors.

The ZW220-6 wheel loader has been named one of the Contractors’ Top 50 New Products of 2021* by Equipment Today, the nationally recognized equipment magazine serving commercial construction contractors.

According to the publishers, “Winning products represent the leading edge of innovation, quality, efficiency and productivity in the construction equipment field today.”

You can read the editors’ comments the #ZW220 in their report from April, 2020.

To see the ZW220 in action, watch its video highlights here:

* Due to industry interruptions by the Covid pandemic, the 2021 awards include new products over a 16 month period from March 2020 to June 2020